Underfloor cooling system – guidelines for installation and use of a layered wooden board

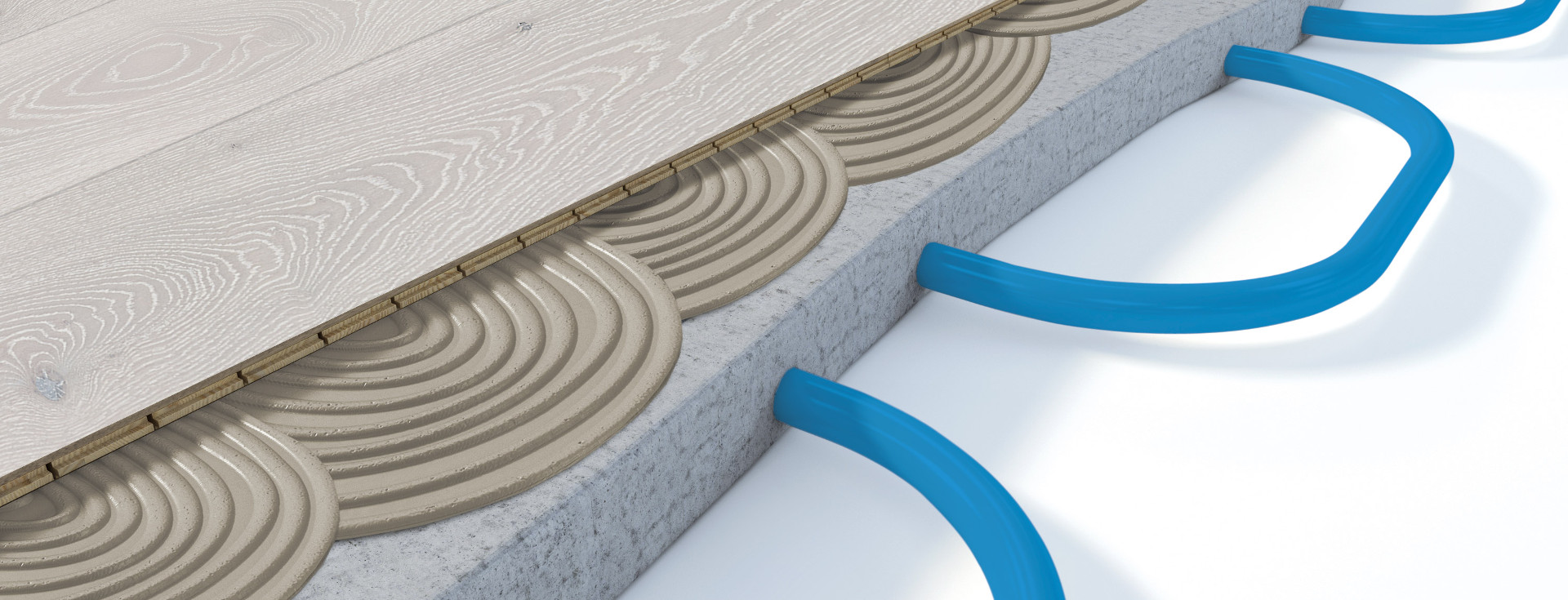

Water underfloor heating systems can be used to cool rooms during hot summer days. The combination of underfloor heating and cooling systems should be established already at the building design stage. An underfloor cooling system is a system in which the floor structure absorbs heat from the room, thus reducing its temperature. The factor that absorbs the heat is cold water supplied to the pipes sunk into the screed. This solution makes it possible to achieve a comfortable room temperature without using traditional air conditioning. In rooms with very high level of sunlight, the underfloor cooling system will perform its function very well, continuously absorbing heat from the air through the cooled floor. This is in accordance with the thermodynamic principle of heat flow from a warmer to a colder medium.

Advice for installers and users – compliance with these guidelines will give you the basis to maintain the warranty.

- It is very important that the underfloor cooling is equipped with appropriate control systems that protect against the condensation of water vapour on the floor surface. To prevent this, the temperature of cold water in the pipes should not fall below a certain value. In every room with an underfloor cooling system, a sensor should be installed that calculates the dependence of relative air humidity on the surface temperature of the board and cuts off the supply of cold water before reaching the so-called dew point, i.e. the condensation of water vapour on the surface of the boards. Lack of such protection may cause the penetration of condensed water from the air on the floor, causing uncontrolled humidification of wood resulting in damage to the wooden floor, such as deformation, discolouration, formation of gaps between the boards.

- Indoor thermostats should not be set to a temperature lower than 23°C. In addition, the temperature difference on the thermostat, and the temperature in the room should not be greater than 5°C. Example: room temperature 30°C, temperature set on the thermostat min. 25°C.

- The underfloor cooling system should be protected against the water temperature dropping below 18°C.

- The maximum thermal resistance of the installed floor should not exceed R≤0.15m2K/W. If the wooden layered board is installed in a floating system, the thermal resistance of the base material should not exceed 0.05m2K/W. In order to achieve a minimum thermal resistance, Manufacturer recommends a glued floor assembly system.

- Switch off the underfloor cooling 24 hours before installing the floor. Once the floor has been installed, the system can be restarted after 24 hours.

- The humidity of the cement screed should be up to 1.8% maximum and that of the anhydrite screed up to 0.3%. Measurements should be made using the carbide method, so-called CM.

- Other parameters of installation and use are in accordance with the installation instructions and conditions of use of wooden layered floors.

- The decision to use underfloor cooling requires a thermal balance to be established at the design stage. Omitting this stage can lead to faulty equipment selection and insufficient operation of the entire cooling system.